March 10, 2017 | Problem Solved | Adam Tesco

Case Study: Lexan Machined & Formed Separation Plate

A customer of ours working with a client in the medical industry, brought a new problem for us to solve recently.

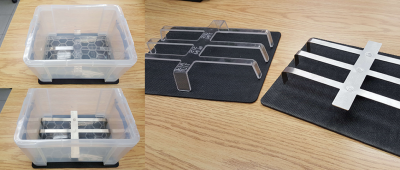

Their client was selling medical devices to a large Canadian retailer that required separation and labeling inside the cases that the devices were being sold in. Their current solution was a costly stainless steel plate with tab insert in the centre that was placed at the bottom of the case to hold the devices in place.

Our customer was looking for a cheaper alternative to this solution that could provide the same purpose to help reduce the cost of the kit to their client.

From day one, we worked with our customer to find a more affordable alternative material to stainless steel that we could not only cnc machine in-house, but also etch with the information required to keep each section of the plate labeled. We decided on Lexan, a high-strength clear plastic (polycarbonate) that could withstand the demands of inserting into the case as well as shipping and transporting to the retailer.

We modified the design of the part to be one piece instead of two, eliminating the center tab in the plate which would have required a secondary part to be machined (additional setup, time and labour). In addition, we suggested bending the legs of the finished Lexan part to hold it secure in the bottom of the case.

The final part created a cost-effective solution for our customer and their client, reducing the clients part cost by almost half in the process.

The CNC machining, etching, forming and bending were all done in house by Electrowind Converting Solutions and delivered to our customer by their requested date.

We offered design and prototype support, low minimums, quick turnaround and dramatically reduced the cost of our clients part at the same time.

Let us help you next. From wine racks to stained glass art to custom pickle ball rackets, Electrowind Converting Solutions has helped a wide variety of customers with their manufacturing problem. You could be next!

Skip to main content

Skip to main content